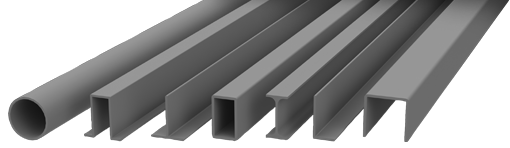

GRP Standard Profiles

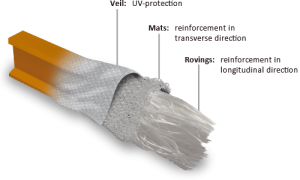

A wide range of different shapes makes it possible to use Standard Profiles in almost every application. In general, all GRP Profiles are cross-reinforced with mats. Unidirectional glass fibre roving in the centre of the profiles carry the longitudinal forces. To improve protection against UV-radiation and wear-out a surface veil can be used.

Also take a look at our Construction Profiles here

Advantages of Reinforced Plastics

- operating conditions from -100°C to +180°C

- self extinguishing and halogen free

- linear behaviour

- low weight

- electrical insulating

- chemical resistant

- corrosion and weather resistant

- UV resistant

- economic efficiency

- high strength

- easy assembly, short construction period

- metal free – non-magnetic

- electrical grounding is not required

- no further maintenance is necessary

- easy to work on, even on-site with the use of common hand tools

- no ridges when drilling and sawing

- for indoor and outdoor application

As a standard, isophtalic polyester resins are used for the matrix. To fulfill special requirements the following resin types are applied:

- vinylester resin: extreme corrosion resistance

- phenolic resin: high temperature and fire resistance

- epoxy resin: special electrical properties

- acrylic resin: low smoke emissions in case of fire

This post is also available in: Swedish Norwegian Bokmål