Dimensional Tolerances

| Property | Tolerance | ||

|---|---|---|---|

| Profile height and width of flange | |||

|

Nominal dimensions (mm)

|

||

| Diametre of Rods and Tubes |

|||

|

D, d (mm) 0 – 10 |

D ± 0,20 |

d ± 0,20 |

| Wall-thickness of open and closed profiles |

Nominal dimensions (mm) | ||

|

Thickness 0 – 2 |

T1 ± 0,15 |

T2 ± 0,30 |

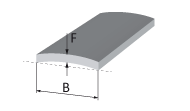

| Flatness in transverse direction | |||

|

Tolerance F < 0,008 X B mm |

||

| Size of angle | |||

|

Tolerance Y ± 1,5° |

||

| Straightness | |||

|

Tolerance (B and H are overall

|

||

| Twist | |||

|

Tolerance

|

||

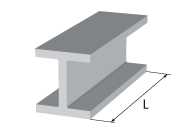

| Length of cut | |||

|

L + 20 / – 0 mm | ||

| Angularity of cut | |||

|

V ± 1,5° | ||